Glass Shaping Machine

With a large - diameter inlet and a high - performance crushing chamber, this equipment can handle materials of varying hardness and block sizes with ease. It produces minimal powder, ensuring high -

+8615053175377

+8615053175377

info@lingbocnc.com

info@lingbocnc.com

Introducing our latest Glass Crusher, a top - tier addition to our lineup of high - performance crushing machines. Engineered to streamline the recycling process, it takes the complexity out of glass waste management. Designed specifically to shatter glass bottles, jars, and various containers, it simplifies disposal and recycling efforts.

Crafted with practicality, convenience, and efficiency at its core, our Glass Crusher is built to last. Constructed from premium materials, it offers exceptional durability and reliability. Capable of handling large volumes of glass waste effortlessly, it's a perfect fit for businesses of any scale.

What truly sets our Glass Crusher apart is its compact and portable design. Lightweight and highly maneuverable, it can be used anywhere, making it an excellent choice for small enterprises and mobile recycling initiatives. Its intuitive, straightforward design ensures easy operation, allowing even industry newcomers to use it without a hitch.

Our Glass Crusher features a robust motor that effortlessly crushes glass bottles. Its blades, crafted from high - grade stainless steel, deliver peak performance and extended durability. Engineered with energy efficiency in mind, it helps you cut down on long - term energy expenses.

Beyond its functional benefits, our Glass Crusher is an eco - conscious choice. By minimizing the amount of glass waste sent to landfills, it effectively reduces our environmental impact. Additionally, since recycling glass consumes far less energy than manufacturing new glass, using our crusher not only helps you contribute to a greener planet but also saves you money simultaneously.

In a nutshell, our Glass Crusher is an innovative, high - efficiency solution tailored for businesses aiming to slash waste volume and cut disposal costs. Its compact, portable build, premium materials, potent motor, and energy - saving operation make it a great fit for companies of every scale. Whether you're a startup seeking a recycling fix or a major corporation ramping up sustainability efforts, our Glass Crusher is the ultimate pick. Reach out to us today to discover more about our offerings and how we can assist you in hitting your recycling targets.

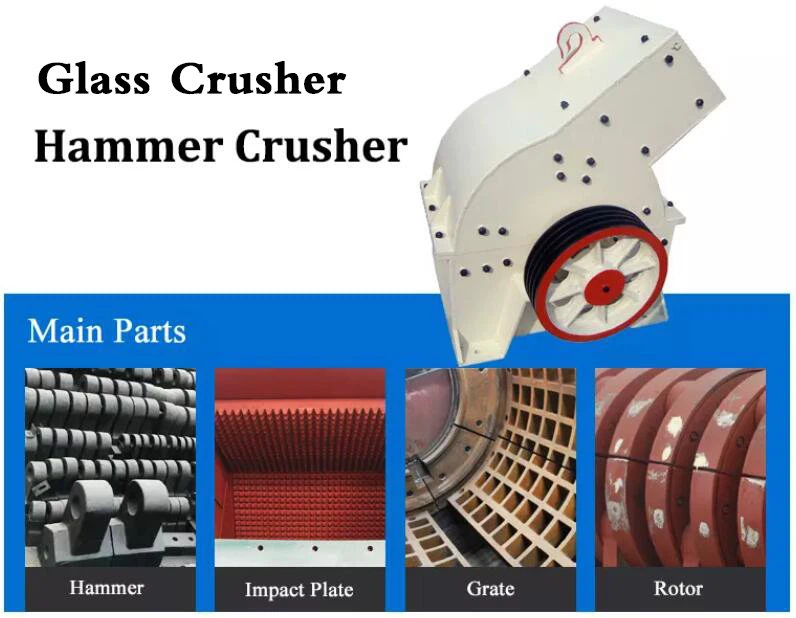

Large Inlet and High - capacity Crushing Chamber: It can handle materials with different hardness levels and block sizes, and produces less powder in the final product.

Low Power Consumption during Idle and Crushing: It consumes less energy both when there is no material and during the crushing process.

New - designed Hammers with Strong Impact Force: The hammers deliver powerful impacts for efficient crushing.

Adjustable Hammer Shaft Installation: This design extends the service life of the hammers.

Adjustable Grid Size: Enables control over the particle size, resulting in a good - shaped final product.

Flip - up Chassis: Facilitates easier maintenance work.

Square - shank Bolts: Offer excellent impact resistance and wear resistance.

Compact Structure with High Rigidity: The machine is space - saving yet sturdy.

User - friendly Structure: Easy to handle and install.

Integrated Functions: Combines shock, counter - strike, and impact (rock crushing) functions, achieving high production efficiency, low mechanical wear, and a significantly improved overall performance. It is widely applied in the artificial sand production industry.

In a hammer crusher mill, the motor drives the rotor to spin at high speed via a belt. The rotor is equipped with a series of hammers. When materials enter the hammers' working area, the rapidly rotating hammers crush them. Crushed products that meet the required size are discharged through the outlet as the final output. Meanwhile, oversized materials are carried back to the crushing area by the hammers and re - crushed until they reach the desired size.

Q: We are first time to hear your brand, are you new to this glass process filed?

A: We are factory built 2014, we have good name in home market, however we just start to open international market.

Q: What is your advantages compared the other supplier?

A: We supply high quality machines with high technology but with lower prices. Because our company goal is to Provide the most cost-effective products for the world.

Q: How about your warranty?

A: The guarantee period shall be 15 months counting from the date of the goods on board, except wear parts. In the normal course of operation and maintenance if there is breakdown and damage, during the Guarantee period (15 months) the repair parts should be supplied by the Seller for free, except wear parts.

Q: What's the payment term?

A: We can accept T/T, L/C, western union etc.

Q: Can we visit your factory before order?

A: Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Q: What's the delivery term?

A: At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15-20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

· LINGBO Insulating Glass Production Machinery with argon Gas Filling onLine is our Patent products, and the reasonable filling way makes the filling result of insulated window glasses high gas utilization rate and high gas filling rate.

· Strong technical support gives us a strong ability to serve customers. Our company is the Unique high-tech enterprise in Shandong Province in the glass processing industry.

· Own independent R&D team, especially employing two top field Korean experts, improving the products better and better, fit for the market better.

· We are having more than twenty patent certificates;

· Everyday, we will install one complete line in home market, so large customer group give us full communication and feedback, making us get a wealth of industry knowledge and equipment installation experience, which is much better to serve next customers;

· Having complete after-sales tracking and service team, able to serve our global customers well;

· Complete protection system for regional distributors to well serve local end customers;

· 7X24 online supports.

Fil the form and send us your message.Get in touch with PAULAIR and find a specialized consultant for you !